Materials for Automotive

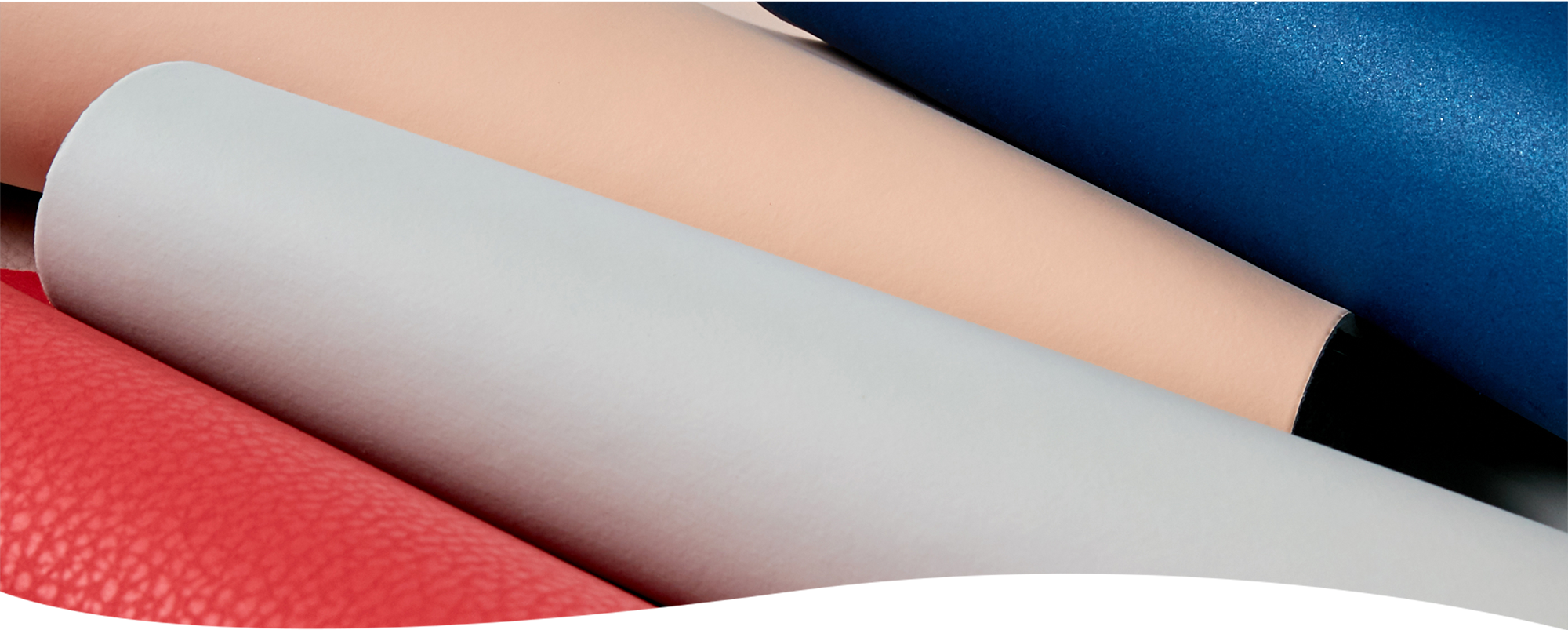

Choice can be a luxury. Gen Phoenix materials offer automakers a more sustainable route to crafting the luxurious and lasting interiors coveted by buyers.

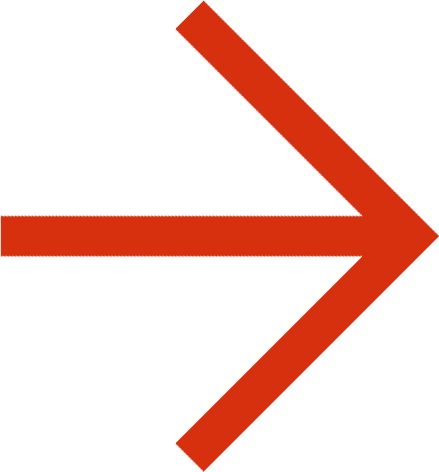

Retaining the time-honored tradition of leather automotive interiors, without the inefficiencies that make it unsustainable—environmentally and economically. With five times the strength than traditional leather, delivered in consistent, production-friendly rolls, Gen Phoenix outperforms leather from the ground up.

Light yet luxe, Gen Phoenix materials respond to the latest wave of eco-conscious customers, helping cars lose 4 kg for fuel savings, reduced emissions, and increased range.

Why the top car companies trust Gen Phoenix

Enduring quality Streamlined production Lower weight Application versatility Limitless Design Potential

Experience the Gen Phoenix difference. Request a material sample