Materials for Aviation

The sky is the limit with Gen Phoenix. Our high-performing, sustainable next-gen materials are up to five times more durable than other upholstery materials.

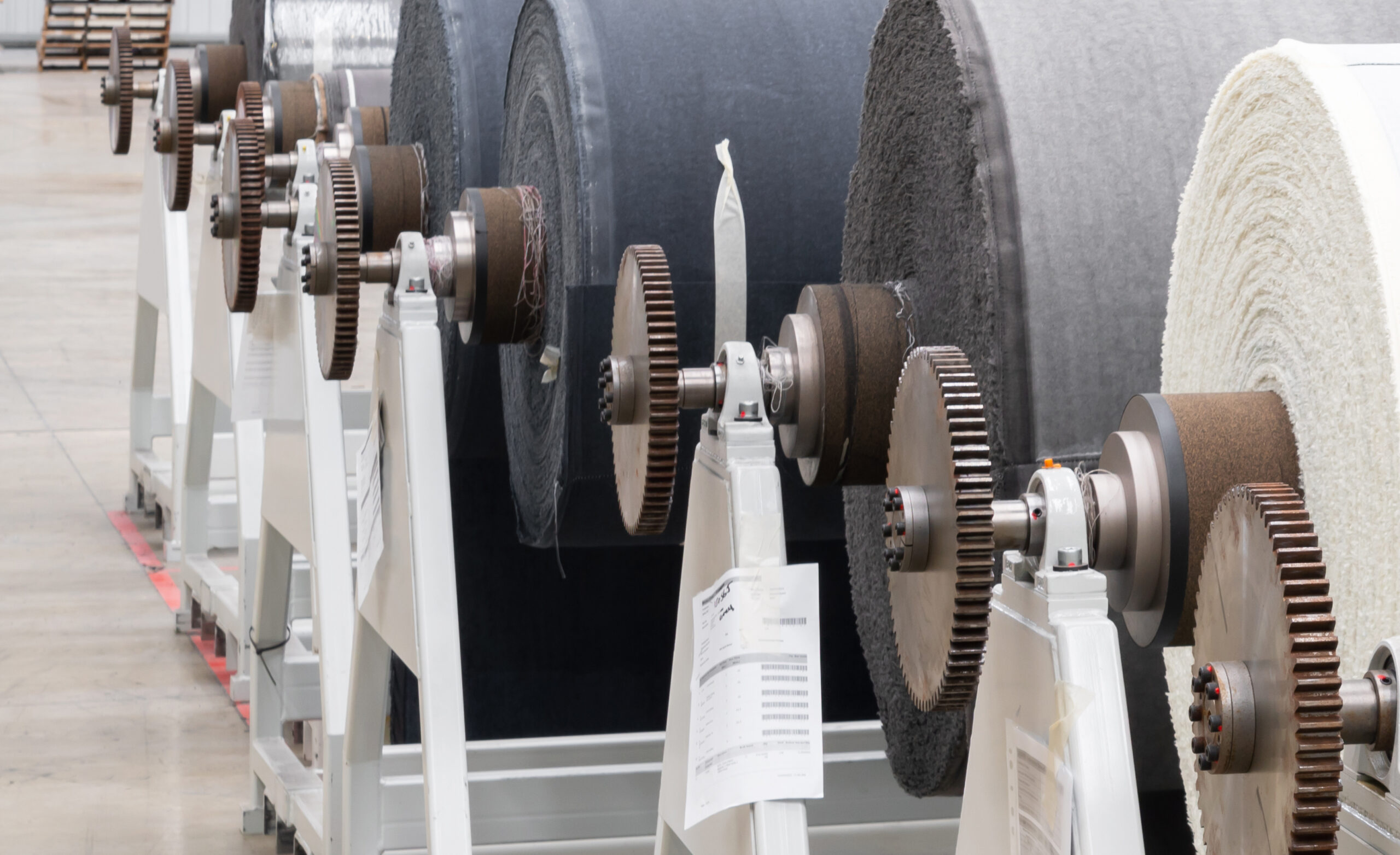

Hundreds of airlines globally use our flagship leather-based product, ELeather, to bring the luxury and performance of leather onboard in a lighter, stronger, and more sustainable profile—saving up to $10k in fuel per aircraft, per year vs. traditional leather.

Meanwhile, our flexible technology opens up radical possibilities for circular sustainability – creating new materials from manufacturing, post-consumer, and end-of-life waste streams.

Why hundreds of airlines trust Gen Phoenix

Advanced durability Infinitely customisable Form meets function Waste reduction Cost efficiency

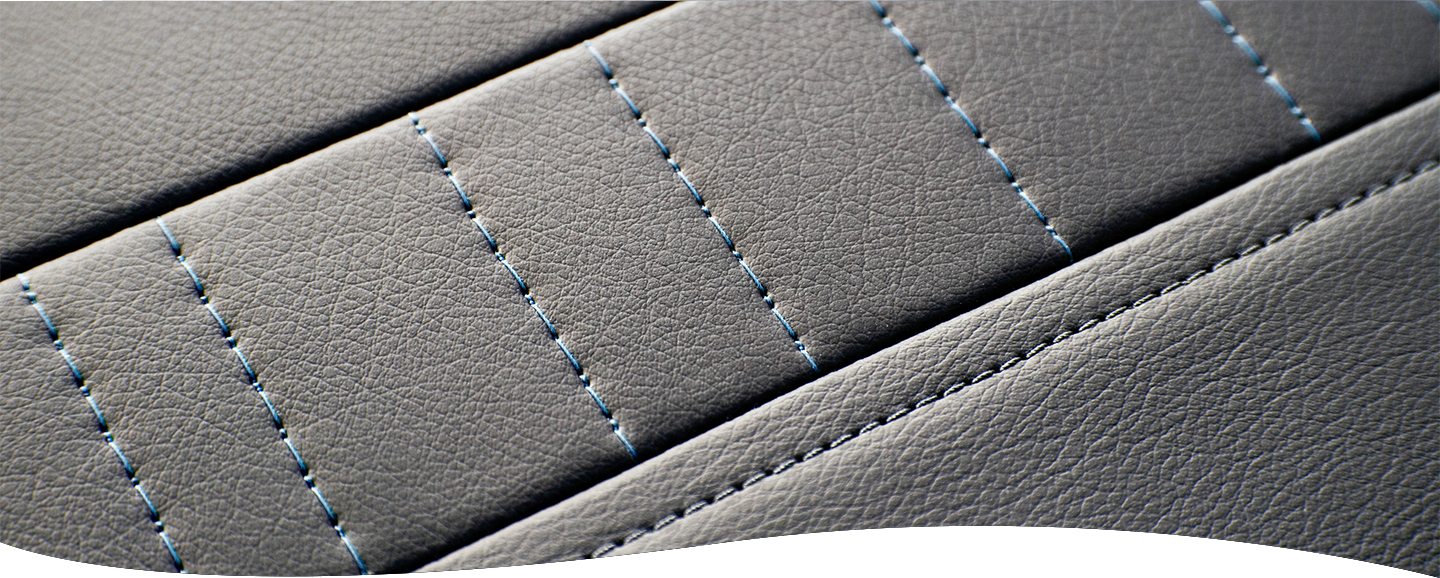

- Anti-scuff and scratch surfaces help seats look better, longer, and require less-frequent replacement.

- No seat bagging or sagging for the life of the product-retains its ‘just been crafted’ look year-after-year.

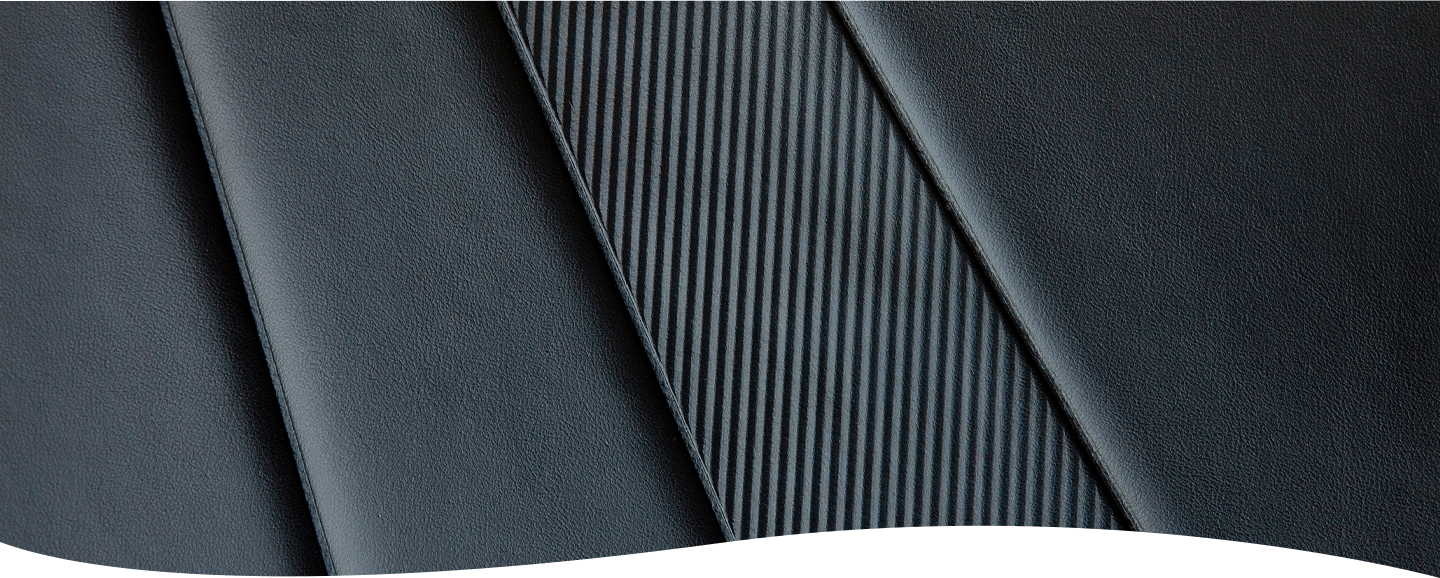

- Offering a mix of stock and bespoke colourways, combined with multiple grains, textures, coatings, and finishes.

- Compatible with a range of design possibilities including embossing, gradient printing, stitching and perforation.

- Materials are designed to to look and feel just as luxurious as full grain leather.

- Customers at some of the world’s largest airlines keep seats in service for over five years with virtually no signs of wear.

- Delivered in consistent, ready-to-cut rolls with 90% usable area per 5 sqm (based on typical seating upholstery application) compared to a maximum of 70% for leather.

- Our take-back program offers reduces end-of-life material waste.

- More than 48% lighter compared to typical aviation leather resulting in reduced fuel costs and, consequently, reduced carbon emissions.

- A longer product lifespan requires less frequent maintenance and replacement.

See it in action. Explore the case studies.